39g Bluetooth Speaker

2021-2022

The 39g is the lightest, loudest and longest-lasting wearable bluetooth speaker on the market. It has a patented design with a unique magnetic attachment that can secure it comfortably to a shirt or metal surface. It also has a traditional spring loaded clip that can be used to secure it to clothing or a bag pack. The powerful neodymium speaker coupled with advanced processing and amplifier circuitry makes it the best in class speaker.

I worked on the development of this speaker extensively during my time as Lead Electrical Engineer at Noxgear. My primary focus was on product updates, supporting manufacturing and doing failure analysis on field failures. I also coordinated the effort to get the product FCC/IC certified. I will dive deeper into some of the interesting work that I did for the 39g.

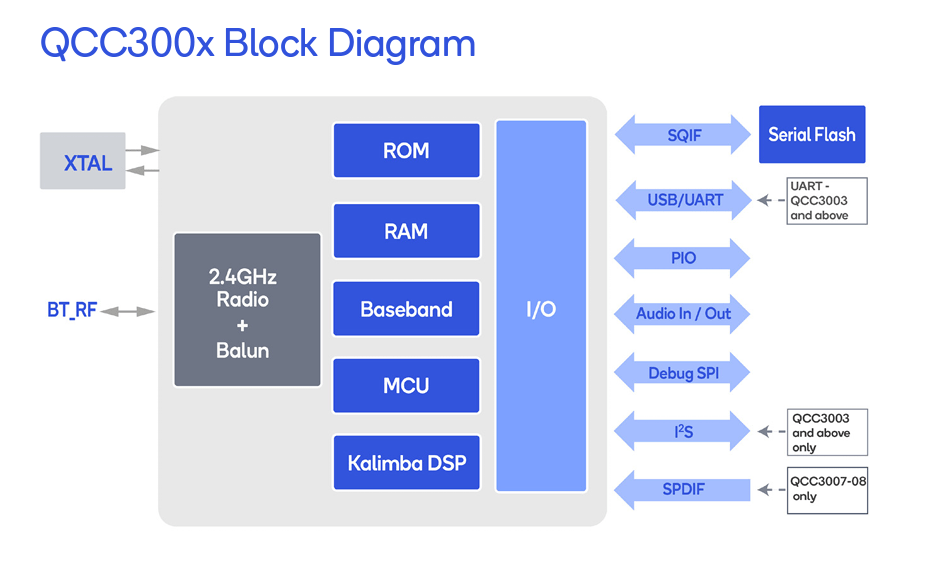

Chip Update

The 39g uses a Qualcomm audio chipset and a big part of the update effort was to swap in the current chipset with a modern one. While that should have been a drop in replacement, nothing in the engineering world is ever that simple. Qualcomm had kept the basic functionality of the chips the same but changed the way it was architected completely. That meant bugs, and there were plenty of them.

I did a lot of testing and validation work to ensure every function of the product worked equivalent or better than before. The chip has a lot of advanced hardware and software features which made it a good choice but had some very fundamental bugs which were very hard to fix. I dove deep into the application firmware that Qualcomm provided and worked on finding the root cause of the various issues and making appropriate modifications to solve them. But getting support from Qualcomm proved to be very challenging so it felt like despite the premium we were paying for it, we were on our own.

I learned that you can never assume that a drop in replacement would actually be a drop in. Testing it fully is crucial. And second, that no matter how big the company, don’t assume the software they wrote for their product will be fully functional.

Switching to USB-C

I am a big proponent of the USB-C connector (despite its issues which I will cover in a separate post) so I made a push to switch the 39g from a Micro-B to Type C. That would have been trivial, but the 39g is designed to be very compact and water resistant. And the original design did not have a lot of room around the USB connector. Also in the manufacturing world, making design changes has a lot of constraints that do not exist the prototyping world.

It was collectively decided that the 3.5mm headphone jack would be retained in the new design so the challenge was to fit this new connector while having minimal plastic mold changes, good water sealing and reliability.

It took many iterations, heated discussions and design changes but we eventually got it. I had to play a lot tricks with the placement, PCB mounting pads and assembly process to ensure that the connector could fit, be mechanically strong and look good.

FCC/IC Certification

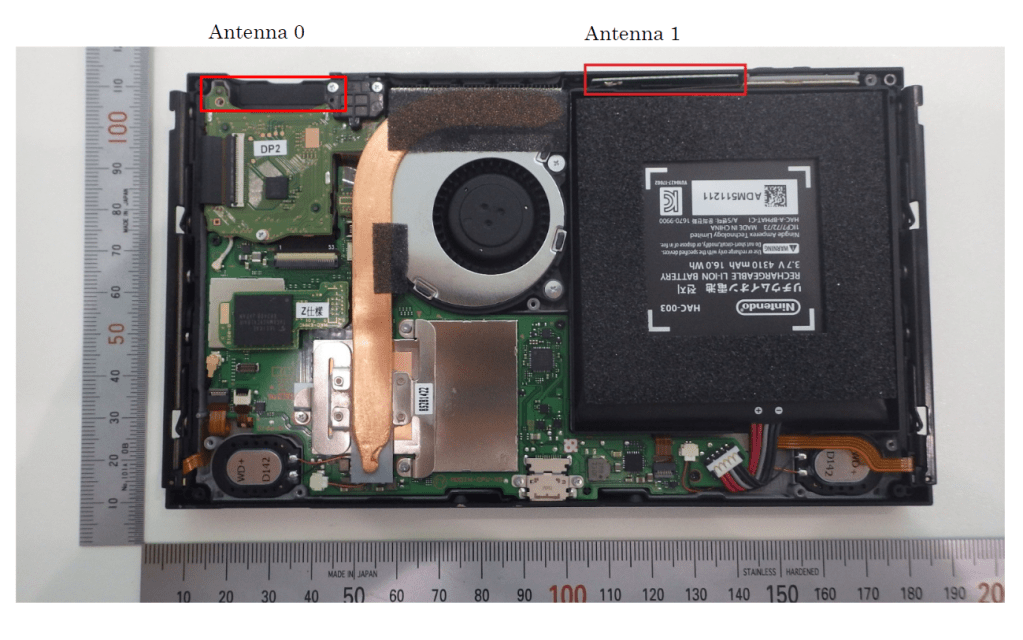

Getting the 39g certified was a great learning process for me. The filing process itself was pretty boring and had a lot of paperwork but what I learned about certification requirements was very valuable. The FCC has strict requirements on RF emissions and how those tests are to be performed. They want to ensure that the product is safe to use even at its maximum transmission power. But the more interesting thing about FCC certification is that the filing has to be in public domain and as a result, you can find internal pictures of most products that are FCC certified.

When I learned about this, I thought I just got a super power because it allowed me to look at the internals of all radio based products of the recent times. You cant get internal images of very recent products since they can keep them confidential for 2-3 years after filing. But the amount of products you can see the inside of, is amazing. If you thought iFixit had a lot of teardowns, wait until you explore the depths of FCC filings.

If you want to search for anything, just enter “<product name> fcc id” in google and go to the result from the website fccid.io. Look through all the documents and find the internal images. Below is an internal image of a Nintendo Switch. You can find the 39g FCC filing here.

Antenna Calibration

As I was working on the PCB for the 39g, I wanted to extract the maximum radio performance from it, and that meant optimizing the RF design. I went through all the basic checks on the PCB to ensure that the traces were 50 Ohms and the antenna cutout was designed according to manufacturer recommendations. But understanding the system and tuning it further was not so straightforward.

One part of the tuning was to understand the antenna radiation pattern and how that interacted with the surrounding components, reference plane and the housing. A simulation tool like Ansys would have been the one to use but it was way too expensive and complex. So we just followed best practice and didnt try anything fancy.

The other part of it was to tune the Pi matching network between the RF TX pin on the chip and the antenna for maximum power transfer. I got a vector network analyzer and spent some time on understanding Smith Charts and S parameters. I attempted my best to tune the network but after a lot of trial and error, I concluded that there was something I wasn’t understanding properly. So we opted to get it tuned from an external service.

My lack of knowledge in RF design bothers me and I hope I can learn more about it and get proficient in RF simulation and tuning.

Testing, testing and more testing

There are plenty more stories but some involve confidential details about the product so I will leave those out. One thing I would say is that if you are designing a product, spend 80% of the time testing the work you did in the other 20%. If you do that, you will end up with a good design.

This is a wall of some of the test units that I performed non destructive testing on. There were buckets of units I did destructive testing on. All in the name of good product design.

Thank you for your attention. Please feel free to ask questions or leave comments. What fun stories can you recall from your work experience?

Leave a comment